Structural Uses Of Coating Machines

87

The coating machine adopts a dedicated coating head, which can effectively reduce the generation of air bubbles. The carrier roller of the coating machine is equipped with a full speed automatic film receiving mechanism, and tension closed-loop automatic control. Compared with ordinary machines, it has unique advantages. During the reverse roller coating process, the gap between the two rollers is relatively small, the capillary standard number is sufficiently low, that is, the viscosity and velocity are relatively small, and the flow is relatively stable within a wide range of velocity ratios, which can achieve relatively good coating apparent quality. When the gap of the coating machine is large, and the speed is high, it is easy to cause air to be drawn in, and there are many small bubbles on the coating surface.

Coater is a green and environmentally friendly coating technology with fast production speed, high efficiency, low cost, small equipment footprint, short investment payback period, and economic investment projects. It has become a huge market development prospect for packaging, automotive, and clothing coating machines. This technology has an increasing proportion of development in the market, and new application fields are emerging in an endless stream.

When producing and processing coating machines, new functions will be added within a certain period of time. This also adapts to the use needs of the coating machine and its own characteristics.

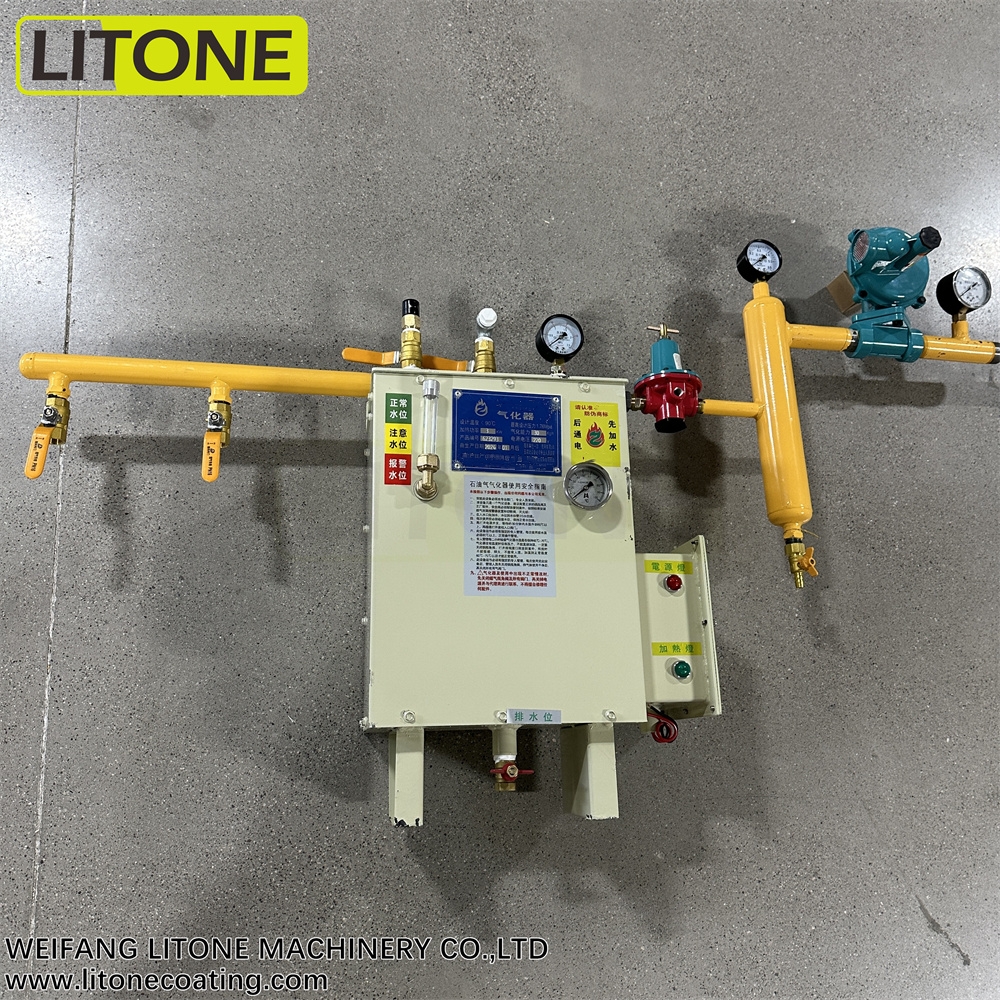

The oven temperature of the coating machine is not fixed, and the multi-level temperature control method is used. Therefore, the temperature can be selected according to the material to improve the drying efficiency of the oven. The heating method of the coating machine is not single, there are many heating methods. Common heating methods include hot blast furnace heating, electric heating, and steam heating. When heating different materials, you can choose the heating method that is suitable for you, improving the heating efficiency.

In fact, the tension is also controlled hierarchically, and its coiling equipment is also equipped with an automatic deviation correction effect. The edges of the produced product are very neat, without problems such as too rough edges, and product quality degradation.