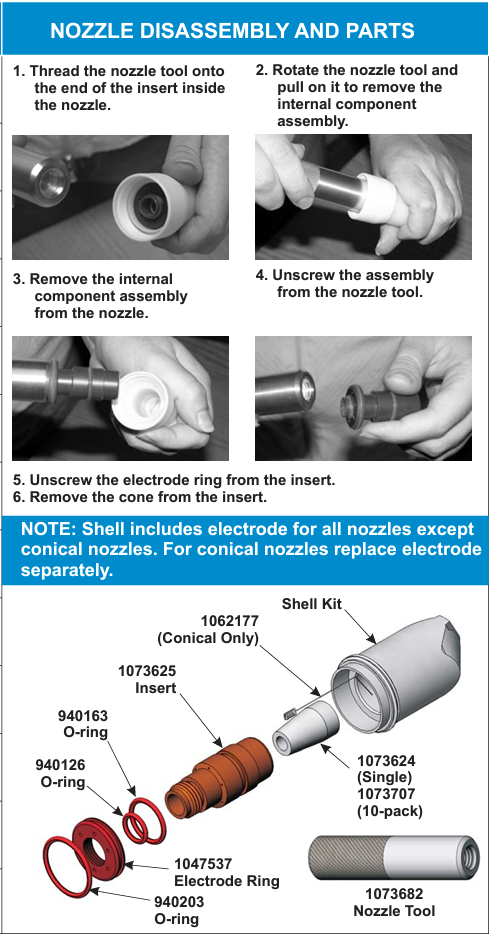

Prodigy Generation II Manual Powder Spray Gun Nozzle Shell/Electrode 1073726/1073706(NON-OEM)

Prodigy Generation II Manual Powder Spray Gun Nozzle Shell/Electrode 1073726/1073706(NON-OEM)【Product Description】100% New and High Quality, In-Kind Shooting!Please check pictures for more details,int···

Features

Prodigy Generation II Manual Powder Spray Gun Nozzle Shell/Electrode 1073726/1073706(NON-OEM)

【Product Description】

100% New and High Quality, In-Kind Shooting!

Please check pictures for more details,interchangeable for the original.

Factory support directly, quality guarantee. no middleman, save money.

OEM is welcomed.

| NOZZLE | COMPLETE KIT | SHELL HIT | EFFECTIVE PATTERN SIZE | USAGE |

| Dual Slot Flat Spray | 1073706 | 1073726 | 8 to 10 inches (203 to 254 mm) | General use on manualor automatic guns |

| 75°SingleSlot Flat Spray | 1077385 | 1077395 | 4 to 6 inches (101 to152 mm) | Manual coating and touch-up |

| 90° SingleSlot Flat Spray | 1077382 | 1077394 | 7 to 9 inches (178 to 229 mm) | Manual coating and automaticdedicated areas |

| 115° SingleSlot Flat Spray | 1077388 | 1077396 | 9 to 11 inches (229 to 279 mm) | General use on manualor automatic guns |

| 140°SingleSlot Flat Spray | 1077392 | 1077397 | 11 to 13 inches (279 to 330 mm) | Large flat surfaces |

| 180°SingleSlot Flat Spray | 1073911 | 1077393 | 13 to 15 inches (330 to 381mm) | Large flat surfaces |

| 100°Conical | 1062166 | 1062161 | 6 to 8 inches (152 to 230 mm) | General use on manualor automatic guns |

| 70° Conical | 1062223 | 1062160 | 4 to 6 inches (101 to 152 mm) | General use on manualor automatic guns |

| 40°Conical | 1073819 | 1073818 | 2 to 4 inches (51 to 102 mm) | Manual coating and touch-up |

| 60° Crosscut | 1077584 | 1077893 | 3 to 5 inches (76 to 127 mm) | Manual coating and touch-up |

| 90°Crosscut | 1077585 | 1077894 | 2 to 4 inches (51 to 102 mm) | Manual coating and touch-up |

| 6 Slot Crosscut | 1077586 | 1077895 | 2 to 3 inches (51 to 76 mm) | Manual coating - deep recesses |

| 10 Hole Pinpoint | 1077587 | 1077896 | Pinpoint | Manual coating - touch-up anddeep recesses |

【Detailed Photos】

【Related Products】

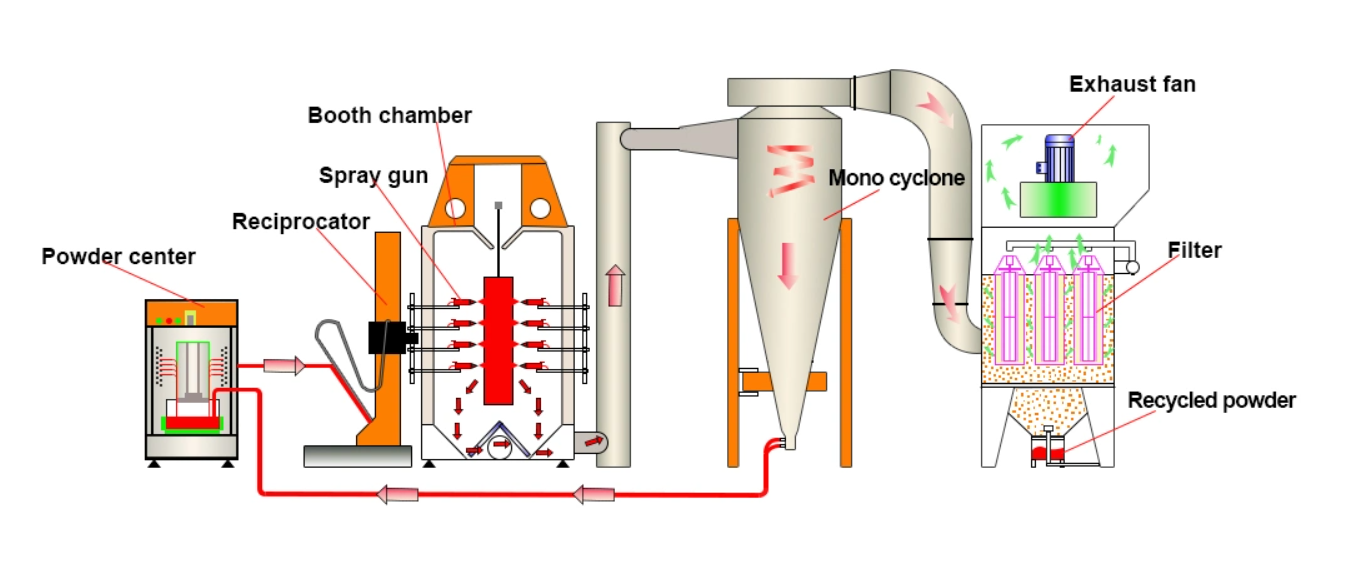

Electrical control system

Electric control of painting line has centralized and single - column control.

Centralized control can use programmable controller (PLC) to control the host, according to the prepared control program for each process automatic control, data acquisitiorand monitoring alarm.

Sinale column control is the most commonly used control mode in the painting production line.

Each process is single column control.

The electric control box (cabinet) isset near the equipment, which has low cost, intuitive operation and convenient maintenance.

The powder coating line is suitable for coating paint and plastic treatment on the surface of the workpiece, and it is used to form the transportation operation with the delivery machinery such as suspension conveyor, electric rail trolley and ground conveyor.

The main components of powder coating line include: powder coating system, pretreatment equipment, powder coating equipment, oven, heat source system, electric control system, suspension conveyor chain, etc. In the process flow is divided into: pre-treatment, powder coating, heating and curing.

Automatic powder coating equipment advantages.

1.the use of automatic powder coating equipment can not only save labor costs, the most important thing is to significantly improve product quality, and to ensure the stability of product quality, so that the smooth and stable production of large quantities, a complete solution to the lack of enterprise productivity.

2. Automatic coating equipment in the coating construction process will not produce irritating odor, not only to prevent pollution and damage to the environment, but also will not cause harm to the physical and mental health of the operator of automatic coating equipment.

3. Automatic powder coating equipment for the first time the utilization rate of powder coating can reach 70%-80%, the coating thickness can reach 60-150 microns, and its powder coating can also be recycled, so the automatic powder coating equipment coating utilization rate can reach 90%-98%. A single coating can get a thicker coating.

4. The powder coating of automatic powder coating equipment does not contain solvent,

5. After curing, the powder coating of automatic powder coating equipment has high plumpness and soft color and because the powder coating does not contain solvent, it is not easy to form pinholes and bubbles when curing. Because powder coating is a solid coating, it will not leak and evaporate during the transportation process.

[PACKAGING & SHIPPING]

Packing: High quality carton and wooden box

Delivery Time: Four to eight days after payment by air

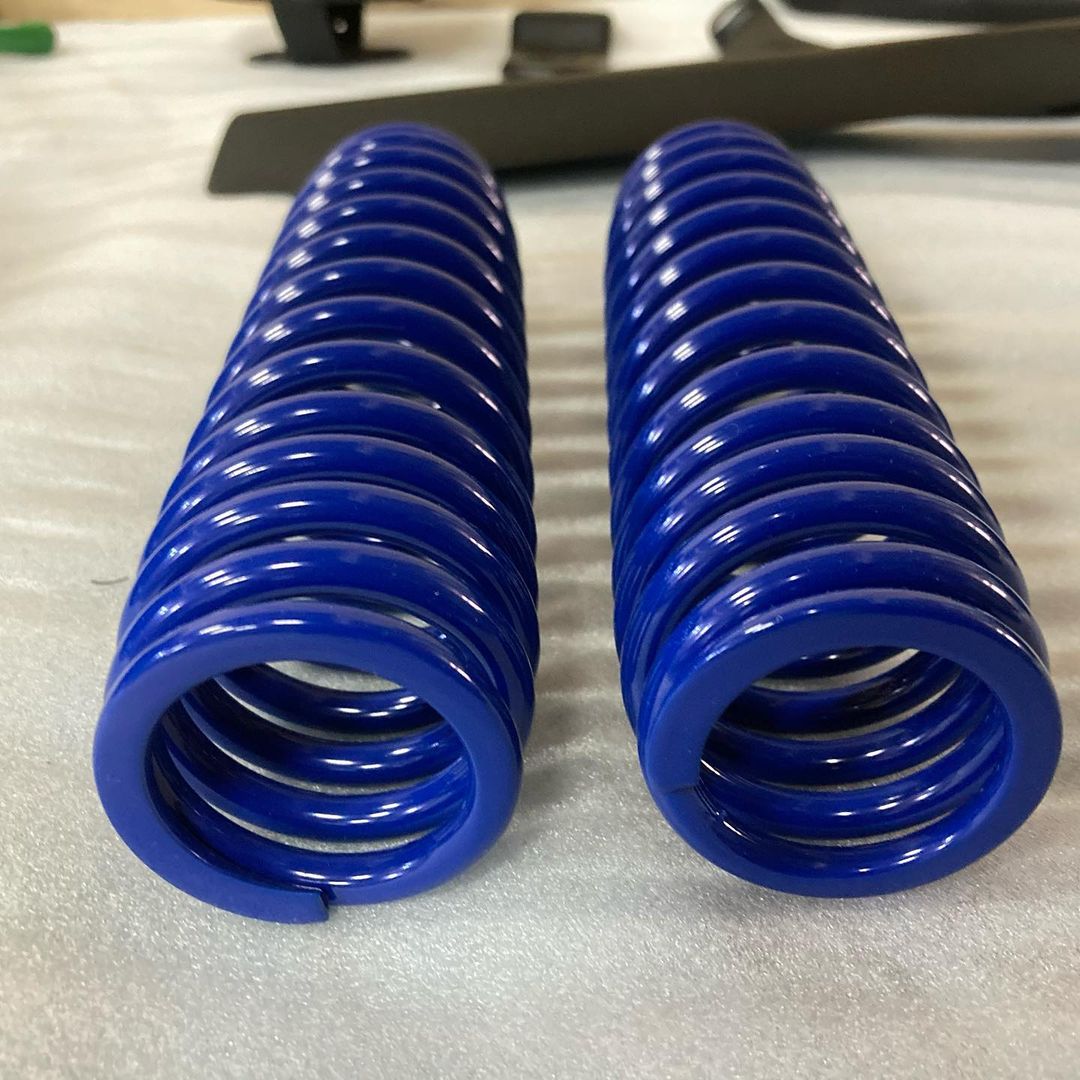

[APPLICATION]

Powder Coating Machine for Metal surface.

Powder Coating Machine for Car wheel.

Powder Coating Machine for Bicycle frame.

Powder Coating Machine for Electrical Household Appliances.

Powder Coating Machine for Aerospace Area.

Powder Coating Machine for Fitness Equipment.

Powder Coating Machine for Track Traffic.

Powder Coating Machine for Medical Devices.

Powder Coating Machine for Petroleum Pipes, Valve.

|  |  |

|  |  |

[LITONE SERVICE]

WeiFang Litone Powder Coating Equipment CO.,LTD specialized in producing and exporting electrostatic powder coating equipment.

We not only supply the high-quality coating equipment,but also the best service.

Our Service:

1. Technology consult service

2. After market service

3. Warranty service

4. OEM service

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

[FAQ]

1. Who are we?

We are based in Shandong, China, start from 2012,sell to North America(25.00%),Southeast Asia(10.00%),South Asia(10.00%),Eastern Asia(10.00%),Mid East(6.00%),Africa(5.00%),Domestic Market(5.00%),Northern Europe(5.00%),Western Europe(5.00%),Southern Europe(5.00%),South America(5.00%),Central America(4.00%),Eastern Europe(3.00%),Oceania(2.00%). There are total about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

Powder coating machine, powde coating line,powder coating gun,powder coating equipment parts

4. Why should you buy from us not from other suppliers?

Our company has more than 10 years of experience in electrostatic spraying industry, and can provide customers with various complex spraying solutions and best services, including: spraying machine, spray gun, spray room, etc

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,DDP,DDU;

Accepted Payment Currency: USD,EUR,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,PayPal,Western Union;

Language Spoken: English,Chinese,Spanish,German,Russian.

[CONTACT]

Litone Machinery Co., Ltd. is a leading supplier in the field of electrostatic powder coatings worldwide.

From simple manual coating to fully automatic powder coating, our company provides solutions that can meet the high requirements of customers from all over the world in a wide range of industrial fields.

These technologically advanced, high-quality equipment and systems are developed and manufactured at Litone's headquarters in Weifang, China.

Customers can use the most advanced coating laboratory for coating experiments.

These findings are then integrated into the design of complex coating systems to tailor solutions for customers. Affiliated companies in Germany, the United Kingdom, the United States, Italy, France, India, Spain and Mexico and an extensive international distributor network in more than 60 countries/regions sell products to a wide range of industrial users.

You Might Also Like

-

![Encore Automatic Powder Coating System Powder Coating Spray Gun Parts Poster 1602674 Clamp Tube(NON-OEM)]() Learn More

Learn MoreEncore Automatic Powder Coating System Powder Coating Spray Gun Parts Poster 1602674 Clamp Tube(NON-OEM)

-

![ND Encore Automatic Powder Coating Machine System Auto Spray Gun Parts 1097514 Gun Harness Receptacle(NON-OEM)]() Learn More

Learn MoreND Encore Automatic Powder Coating Machine System Auto Spray Gun Parts 1097514 Gun Harness Receptacle(NON-OEM)

-

![LITONE ND Encore Auto Gun Spare Parts Powder Tube 1097524 with Seal Tube 1097527(NON-OEM)]() Learn More

Learn MoreLITONE ND Encore Auto Gun Spare Parts Powder Tube 1097524 with Seal Tube 1097527(NON-OEM)

Send Inquiry