Manual Friction Electrostatic Coating Machine T901

Manual Friction Electrostatic Coating Machine T901--Product Description--The working principle of the friction gun is to use frictional electrification to charge the powder.The charge is generated by ···

Features

Manual Friction Electrostatic Coating Machine T901

--Product Description--

The working principle of the friction gun is to use frictional electrification to charge the powder.

The charge is generated by the collision, friction, contact and clutch between the powder and the special polymer material and nylon in the gun wall.

The driving force is air flow.

Advantages of friction gun coating:

1. The first powder application rate is high, which reduces the amount of recycled powder and improves efficiency.

2. Overcome the Faradayon effect, especially effective for coating complex workpieces

3. The powder on the workpiece is more even, and the coating surface has better leveling and smoothness.

4. Comprehensive automatic coating can be used to reduce labor costs.

PNEUMATIC DATA | |

Min.input pressure(dynamical): | 4 bar |

Max.input pressure: | 8 bar |

Max.water vapor content: | 1.3g/m³ |

Max.oil vapor content: | 0.1mg/m³ |

Max.compressed air consumption: | 19Nm³/h |

ELECTRICAL DATA | |

Input voltage: | 100V-250V |

Frequency: | 50-60Hz |

The friction gun has a different charging method and electric field than the high-voltage gun, so the friction gun has its own characteristics. These characteristics show superiority in electrostatic coating.

What are the advantages of electrostatic coat machine friction gun compared to high-voltage electrostatic coat gun?

1. Economy: The powder charging of the friction gun is caused by the friction between the powder and the gun wall, which determines that the friction gun does not require a high-voltage power supply - an electrostatic generator in electrostatic coating. Then save 10-30% of machine investment, especially for small coat machine, the saving ratio is even higher.

2. Safety: It is safer to use a friction gun for coating. This is because there is no high-voltage electrostatic generator in the coating machine. A well-designed high-voltage electrostatic generator will not cause personal injury or death, but the stimulation of high-voltage electric shock will always cause serious injuries. In addition, there are no metal electrodes in the friction gun, so spark discharge caused by electrode short circuit will not occur during coating and ignite the gas-powder mixture.

3. Convenience: It is very convenient to coat with a friction gun. First, the friction gun is not connected to high-voltage cables and is easy to hold. Second, it is less affected by the coating distance. The friction gun is closer or farther from the workpiece, and the coating effect is similar.

4. Advantages: Using a friction gun to coat small workpieces or workpieces with complex surface shapes is much better than using a high-pressure gun. There is no metal electrode in the friction gun, so there will be no powder accumulation on the electrode, which prevents the powder accumulated on the electrode from falling off and ensures that the surface of the powder layer is smooth and flat. The friction gun can be used to coat thicker coated wires, which is incomparable with ordinary high-voltage guns.

--Related Products--

|  |  |

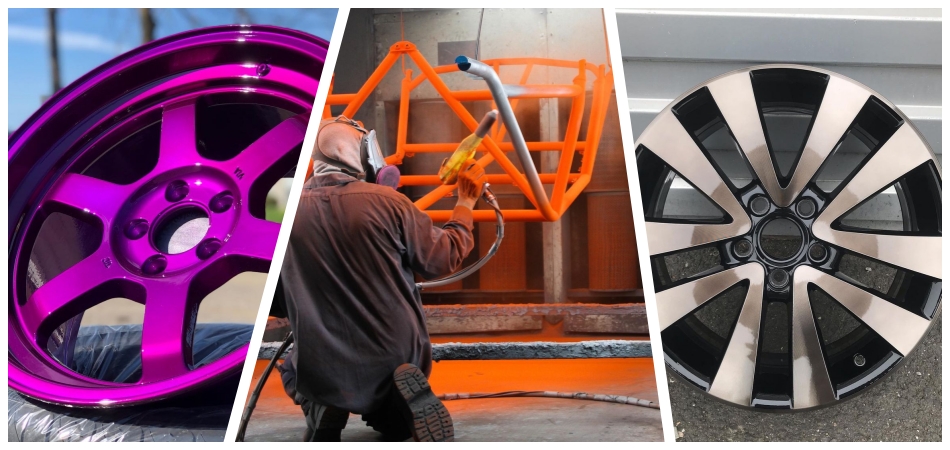

--Application--

Powder Coating Machine for Metal surface.

Powder Coating Machine for Car wheel.

Powder Coating Machine for Bicycle frame.

Powder Coating Machine for Electrical Household Appliances.

Powder Coating Machine for Aerospace Area.

Powder Coating Machine for Fitness Equipment.

Powder Coating Machine for Track Traffic.

Powder Coating Machine for Medical Devices.

Powder Coating Machine for Petroleum Pipes, Valve.

--Packaging & Shipping--

--FAQ--

1. who are we?

We are based in Shandong, China, start from 2020,sell to North America(25.00%),Southeast Asia(10.00%),South Asia(10.00%),Eastern Asia(10.00%),Mid East(6.00%),Africa(5.00%),Domestic Market(5.00%),Northern Europe(5.00%),Western Europe(5.00%),Southern Europe(5.00%),South America(5.00%),Central America(4.00%),Eastern Europe(3.00%),Oceania(2.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us?

powder coating machine,powde coating line,powder coating gun,powder coating equipment,powder coating equipment parts

4. why should you buy from us not from other suppliers?

Our company has more than 10 years of experience in electrostatic spraying industry, and can provide customers with various complex spraying solutions and best services, including: spraying machine, spray gun, spray room, etc

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,DDU;

Accepted Payment Currency:USD,EUR,JPY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,German,Russian

--Company Profile--

Litone Machinery Co., Ltd. is a leading supplier in the field of electrostatic powder coatings worldwide.

From simple manual coating to fully automatic powder coating, our company provides solutions that can meet the high requirements of customers from all over the world in a wide range of industrial fields.

These technologically advanced, high-quality equipment and systems are developed and manufactured at Litone's headquarters in Weifang, China.

Customers can use the most advanced coating laboratory for coating experiments.

These findings are then integrated into the design of complex coating systems to tailor solutions for customers. Affiliated companies in Germany, the United Kingdom, the United States, Italy, France, India, Spain and Mexico and an extensive international distributor network in more than 60 countries/regions sell products to a wide range of industrial users.

WeiFang Litone Powder Coating Equipment CO.,LTD specialized in producing and exporting electrostatic powder coating equipment .

We not only supply the high-quality coating equipment,but also the best service.

Our Service:

Technology consult service

After market service

Warranty service

OEM service

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

You Might Also Like

Send Inquiry