T801 Automatic Enamel powder coating gun

-------------T801 Automatic Enamel powder coating gun -----------------Product DescriptionAdvantage is:1. The utilization rate of enamel can be as high as 70%~90%.2. Improve the gloss of the porcelain···

Features

-------------T801 Automatic Enamel powder coating gun -----------------

Product Description

Product Description

Advantage is:

1. The utilization rate of enamel can be as high as 70%~90%.

2. Improve the gloss of the porcelain surface and reduce the defects of the porcelain surface at the edge.

3. The two-tank-one-burning process can be used and does not require special decarburized steel plates.

4. The dry enamel powder is used directly without grinding it into glaze slurry, and the drying process after spraying is omitted.

Enamel spray gun:

The electrostatic spray gun adopts the high-voltage generation principle. The gun head forms a negatively charged electrostatic field under a voltage of 70~100kV. The workpiece to be sprayed is grounded. When the workpiece passes the spray gun in the spray room, the spray gun starts spraying powder. The positively charged workpiece and the negatively charged workpiece The powders are attracted to each other to form a powder coating. The oversprayed powder is pumped back to the filter system, passed through the filter screen and powder supply barrel, and then recycled to the spray gun.

Product Parameters

Product Parameters

PNEUMATIC DATA

| Min.input pressure(dynamical): | 4bar |

| Max.input pressure: | 8bar |

| Max.water vapor content: | 1.3g/m3 |

| Max.oil vapor content: | 0.1mg/m3 |

| Max.compressed air consumption: | 19Nm3/h |

ELECTRICAL DATA

| Input voltage: | 100V-250V |

| Frequentcy: | 50-60Hz |

| powder charge rate: | 70-90% |

Product Images

Product Images

|  |  |

Related Products

Related Products

Click on the picture to view detailed introduction

|  | |

| T801 Enamel powder coating machine | Automatic Powder sifting machine | Spraying Machine PHIRST |

Our Service

Our Service

Technical consulting services for this spraying machine and related machines

Provide one year warranty service

Save you from worrying about the future and provide perfect after-sales service

You have special needs, provide OEM service

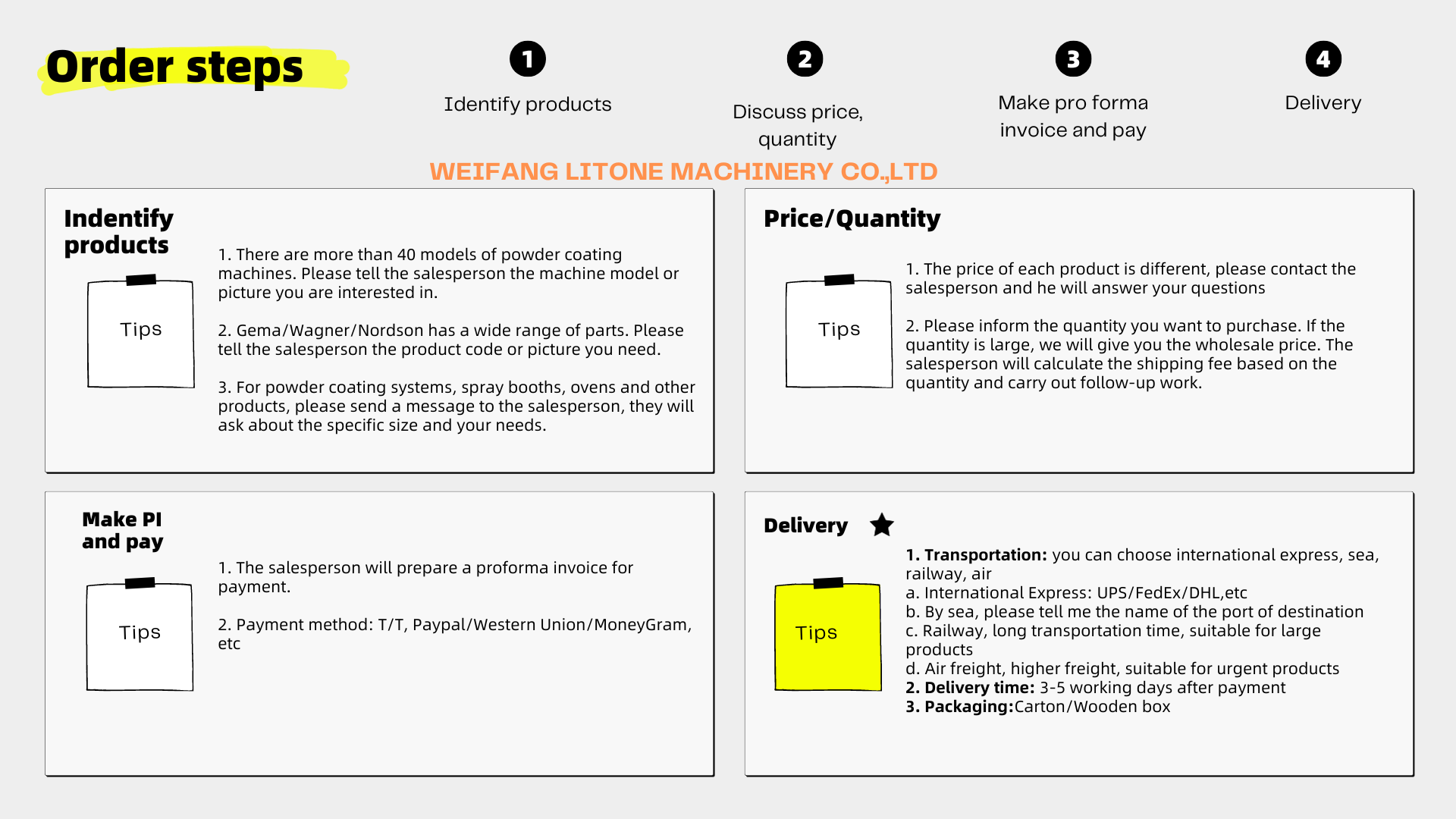

Packaging& Shipping:

Packaging& Shipping:

Carton / wooden box (carton is free, wooden box is charged for packing)

Use multiple shipping methods:

1. International Express: DHL/UPS/FexdEx/EMS

2. Sea shipping

3. Air shipping

We will deliver the goods within 3-7 workdays after your payment, please provide the proof of payment after payment

Certificate

Certificate

FAQ:

FAQ:

1.Application: Used in powder coating machines and production lines, industrial factories.

2.Shipping: can ship to any port by sea, air or courier.

3.Payment methods: T/T, L/C, Weatern Union, PayPal.

4. Packaging: suitable for thickened carton, wooden box, container packaging.

5. Service: We provide various powder coating systems, ovens, powder supply centers, and powder coating equipment, such as booths, hoppers, powder coating machines/control units, electrostatic spray guns, panel controllers, high voltage cascades, PCB, powder injectors/ Parts such as pumps, powder hoses, filters, etc.

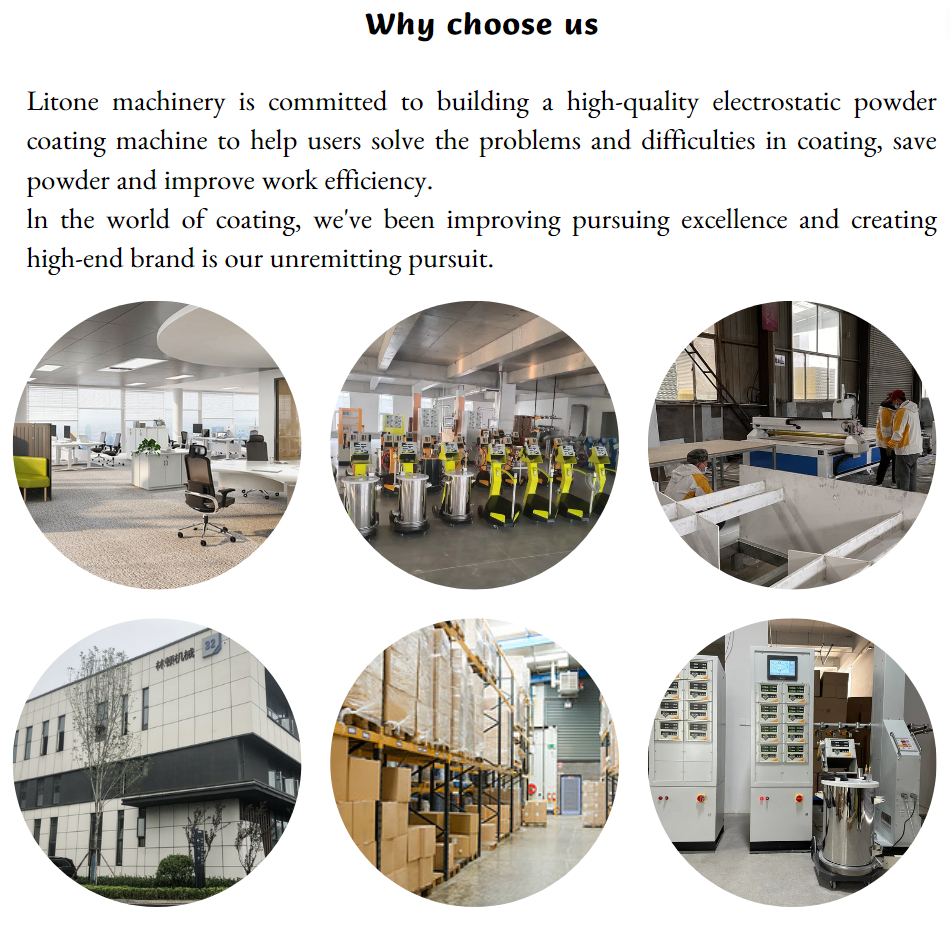

Our Company

Our Company

Weifang Litone Machinery Co., Ltd. is located in Shandong Province, China. It is a typical Chinese supplier, specializing in the development and production of powder coating systems and liquid coating systems. Our products include powder coating machines, spray booths, hoppers, powder coating units, electrostatic spray guns, panel controllers, cascades, PCB, powder injector pumps, powder hoses, filters and other parts, etc.

In addition, we can make various cascades, just provide relevant data.

We not only provide high-quality painting equipment, but also provide the best service. Provide 1-year warranty service, if you have any requirements, you can tell me, I will try my best to serve you.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

You Might Also Like

Send Inquiry